haystack labs

May 23 - 27, 2022

PROJECTS | PRESENTATIONS | NEW EQUIPMENT | PARTICIPANTS | HAYSTACK LABS 2021

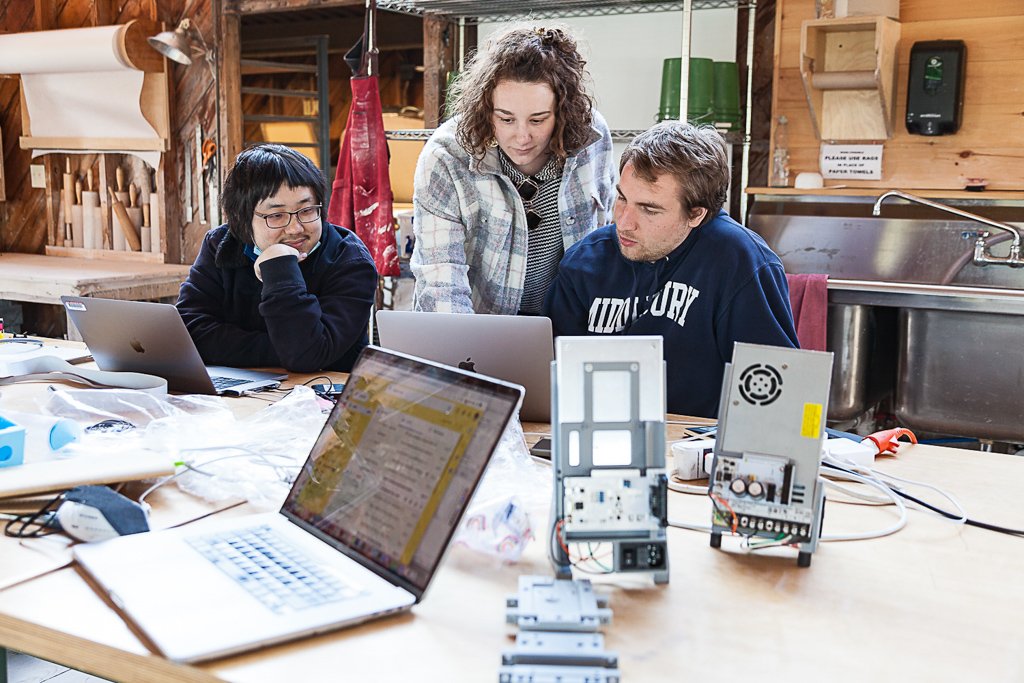

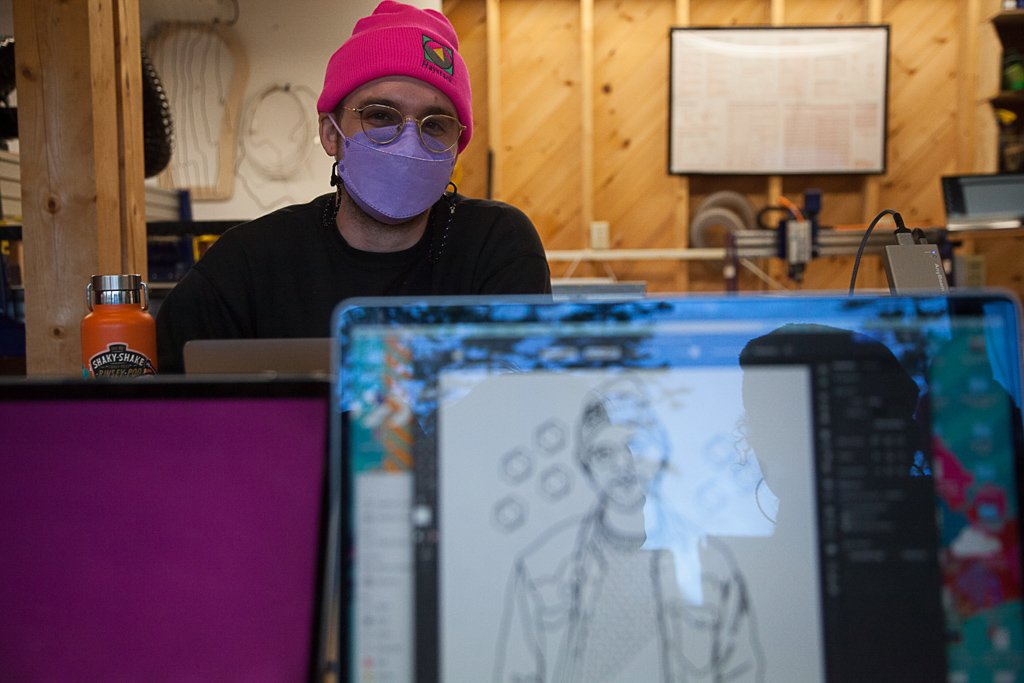

In 2021, Haystack Mountain School of Crafts and the MIT Center for Bits and Atoms developed and piloted an experimental residential program called Haystack Labs. The program aims to bring artists, designers, material scientists, machine builders, and coders together and take over Haystack’s campus and studios to explore the integration of emerging technologies and processes for studio craft. The pilot was so successful that the program ran again in 2022 and expanded to include a broader collection of people from both craft and digital fabrication communities. Over 40 people participated and contributed to various innovative projects that will help inform artists on how to integrate craft and how machine/tool/software designers can best serve creative makers.

Projects

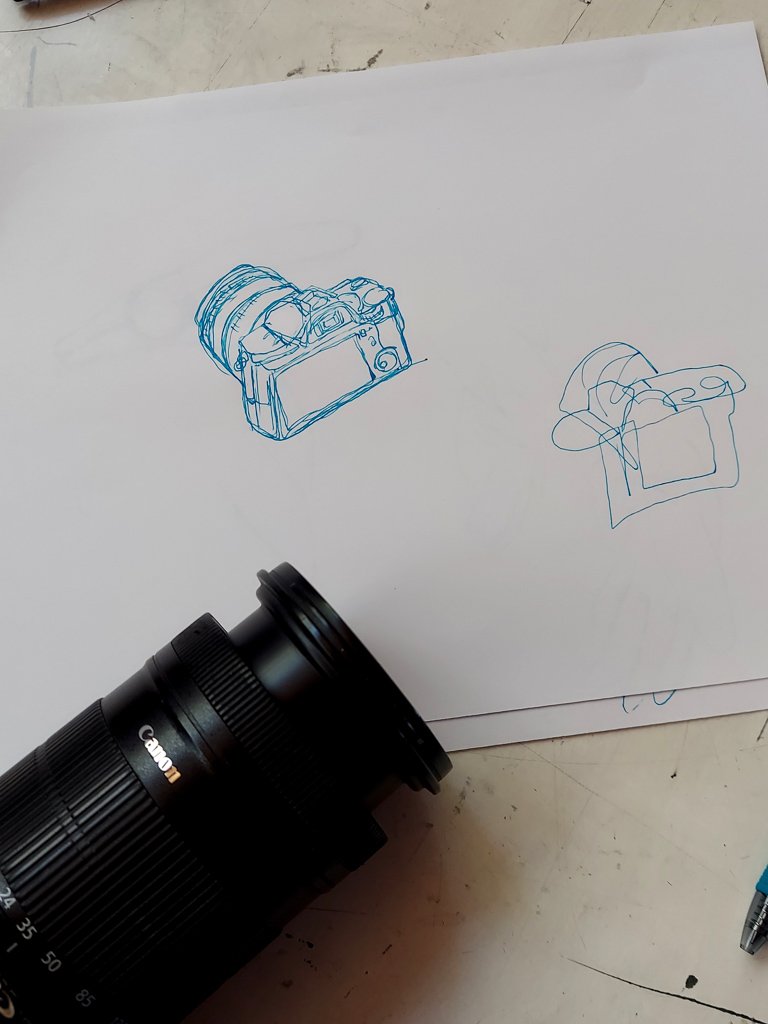

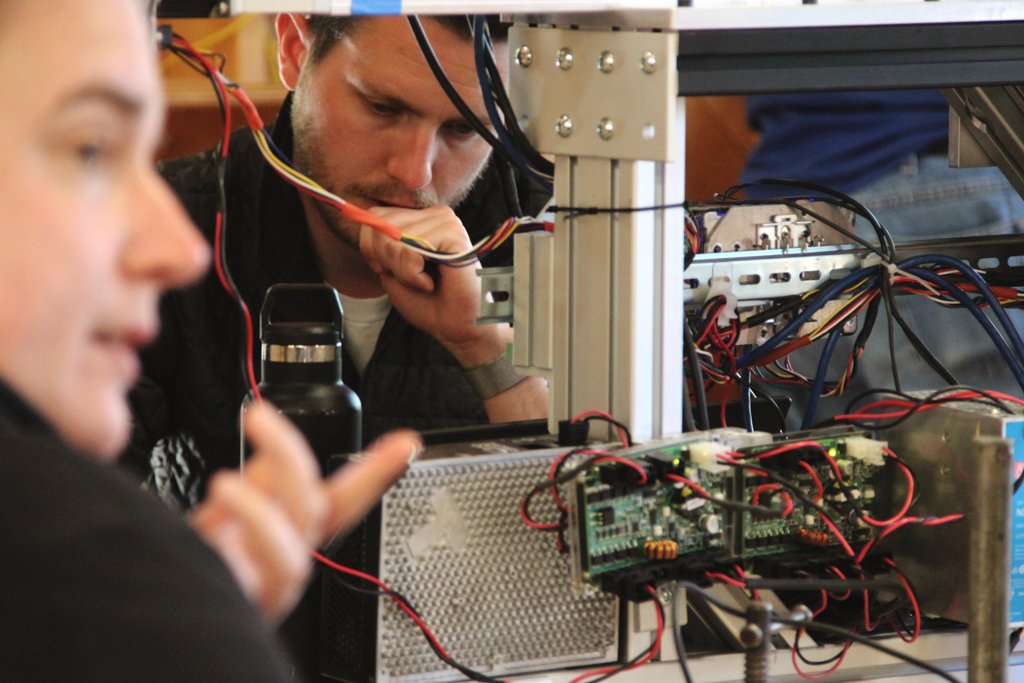

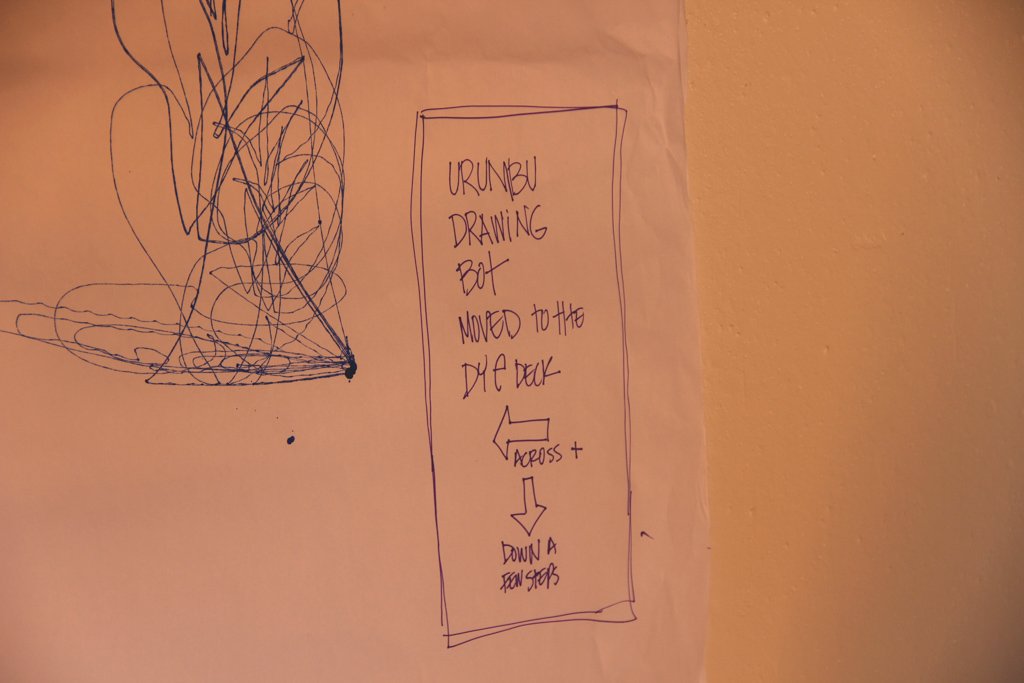

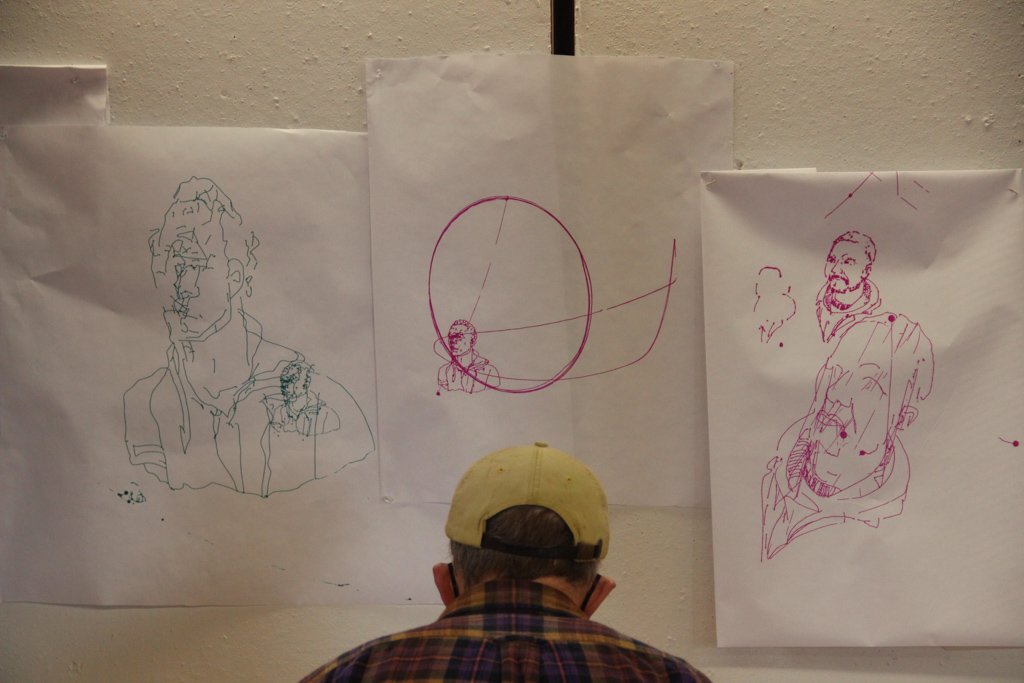

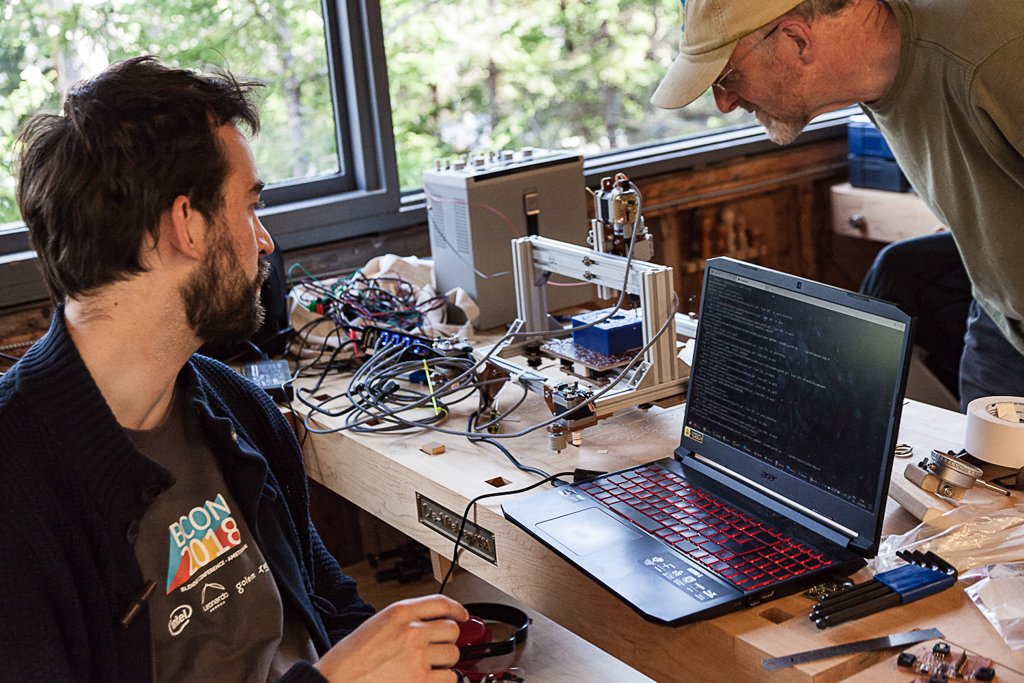

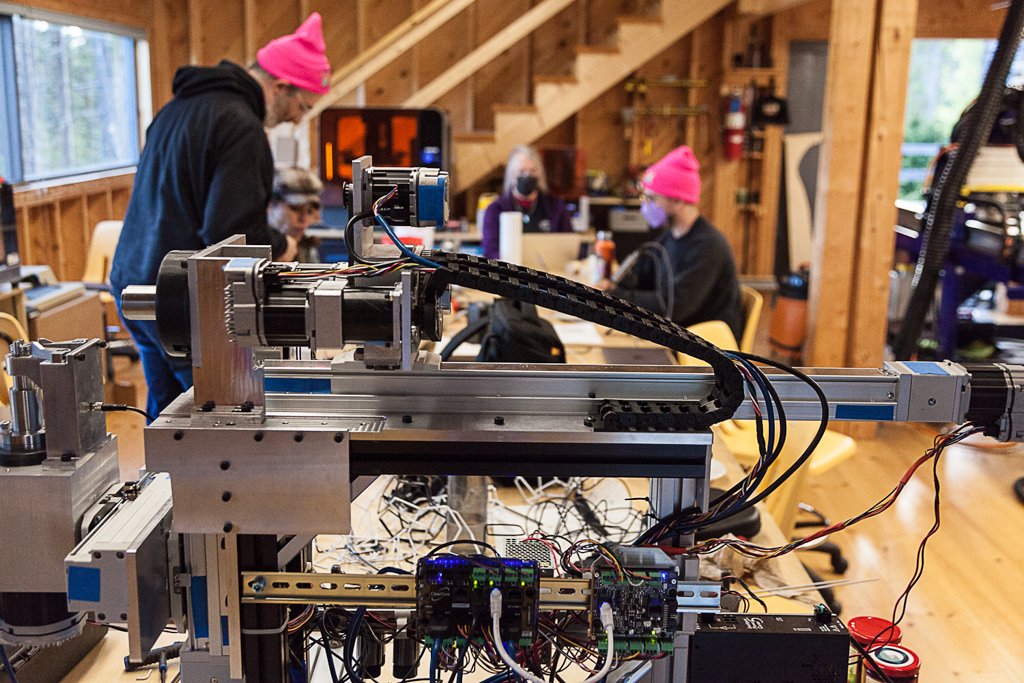

Urumbu II

Rob Hart, Neil Gershenfeld, Shawn Liu, Silvia Lopez Chavez

This project is a continuation of last year’s drawing machine. "Urumbu" is the Malayalam word for small ants found in Kerala, in the south of India, and is used to refer to a machine-building approach that significantly simplifies the hardware by moving all embedded configurations into real-time parallel programming. This is an ongoing project that received significant development during the week, including the addition of a spray paint attachment.

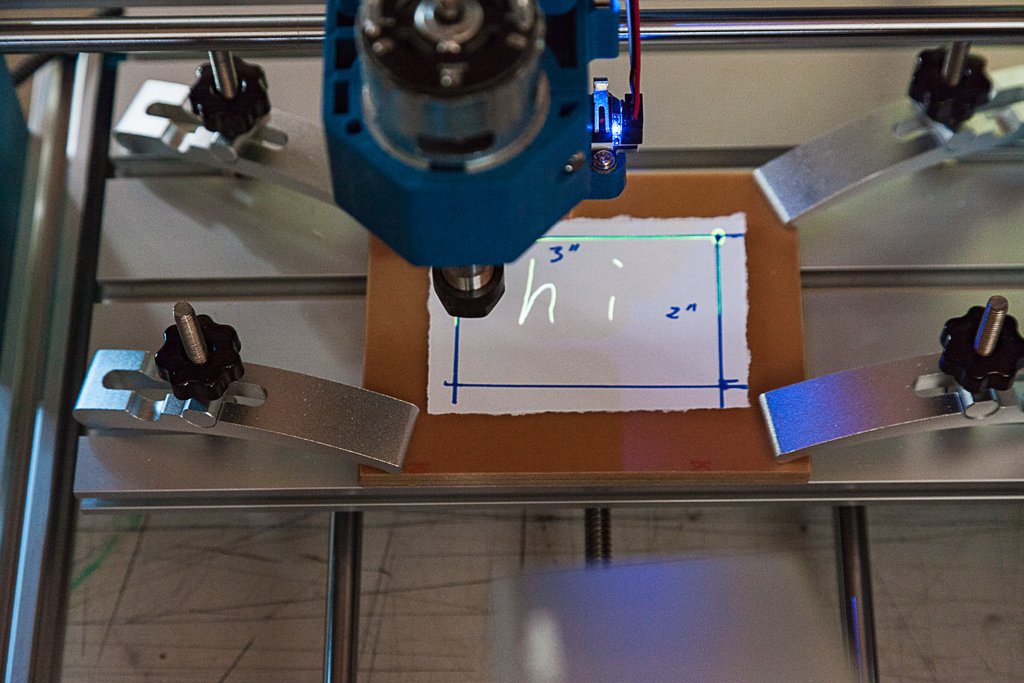

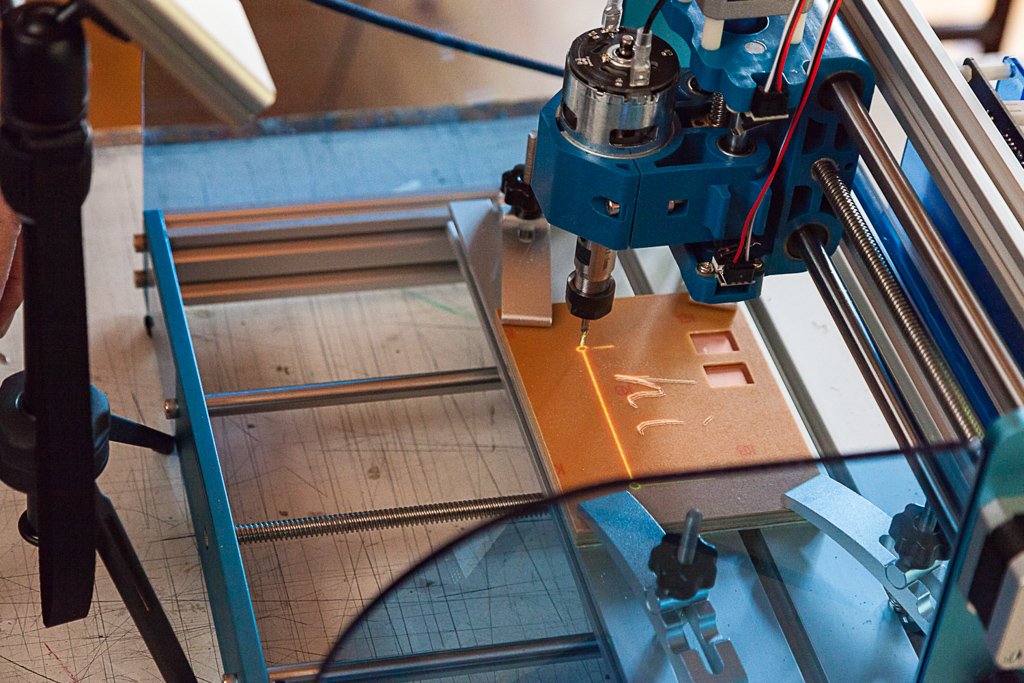

cARv

Ted Hall, Lingdong Huang, Neil Gershenfeld

This project explores real-time machining with the ShopBot Desktop CNC machine using FabMo and an open-source platform for controlling machines. A smartphone running FabMo is used to along with a stylus to draw on the screen and control the motion of the machine in real-time. This is demonstrated in the video, and several wood carvings are created.

AR-assisted CAM without CAD. Referred to as The Tom Boddet Problem, who first raised the issue of CNC machining and the barriers to entry for most woodworkers. On the final working day, this working group could draw directly on the workpiece successfully and then use a pico-projector camera to generate the CAM toolpaths for the machine automatically, without any CAD software involved.

Fabriclaytion

Jennifer Jacobs, Leo McElroy, Kate Reed, Lingdong Huang, Jenna Fizel, Phirak Suon

This project combined several digital tools to experiment with generating digital forms and printing directly with clay using a 3D PotterBot. In one use case, a VR headset (Meta Quest 2) and design software, Gravity Sketch, were used to generate 3D forms suitable for ceramic applications quickly. These designs were then exported and printed directly in clay. In another use case, two participants designed custom generative design software to allow for the easy creation of complex shapes and forms.

Draw and Grow lets you sketch lines which you can evolve with a differential growth algorithm. The evolution of the shape forms a 3D object which you can export to PotterBot gcode.

Swarm Interpolation allows the designer to specify cross-sections of a shape. These cross sections are then connected by a swarm of particles that preserve certain features between intermediate cross-sections (like the number of islands).

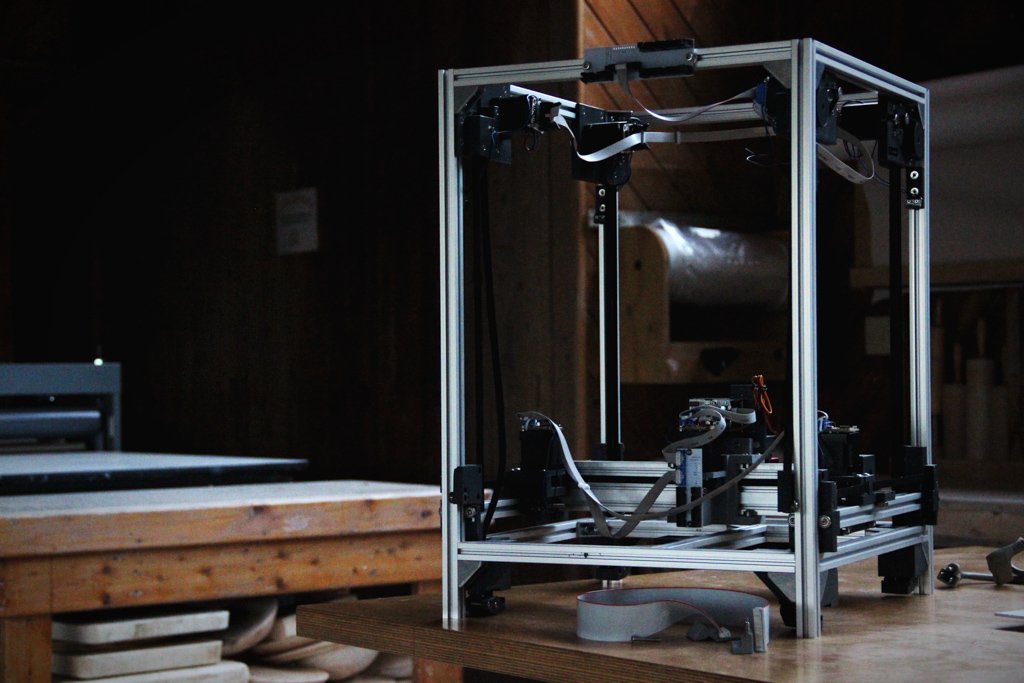

Origamachine

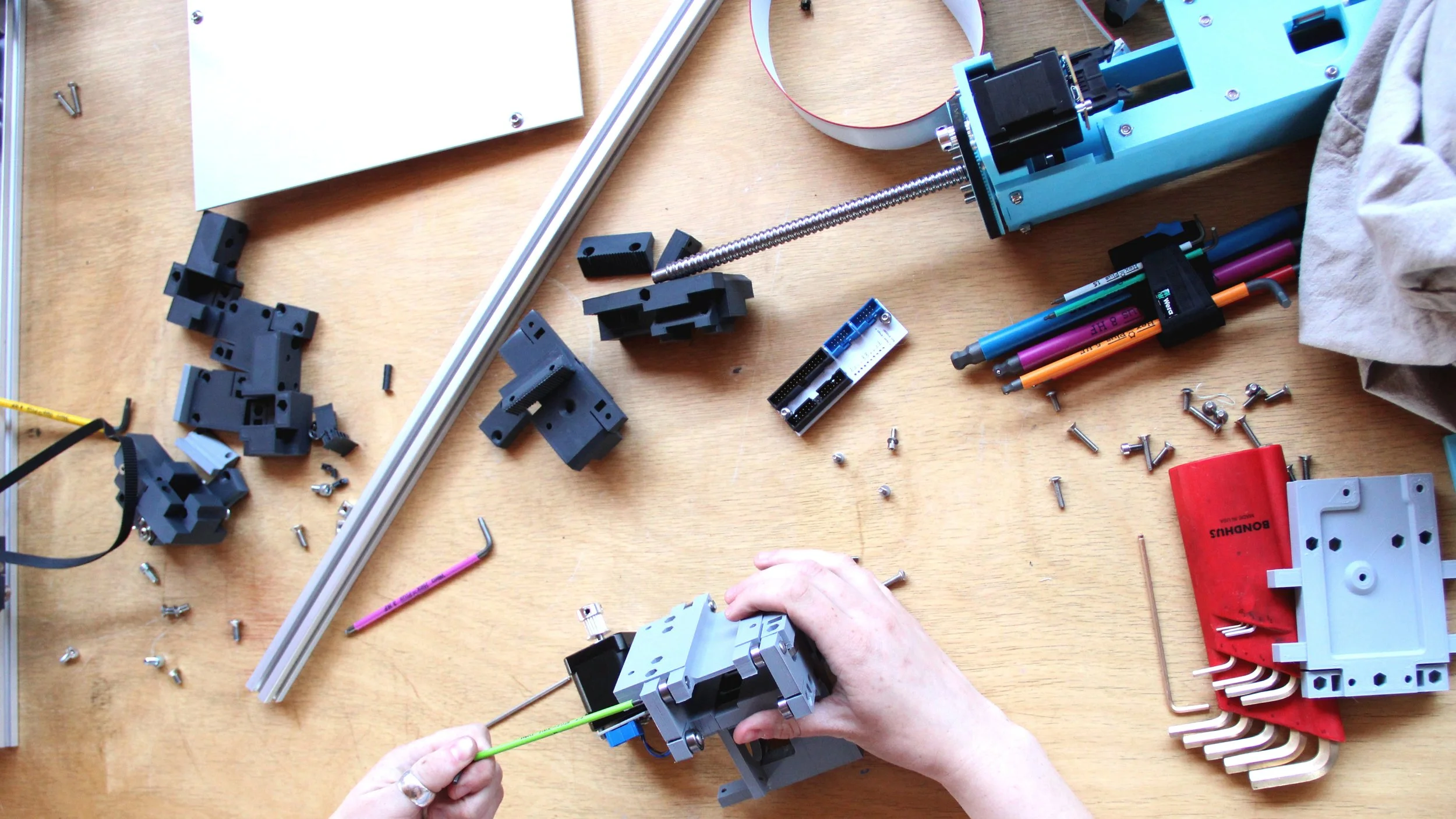

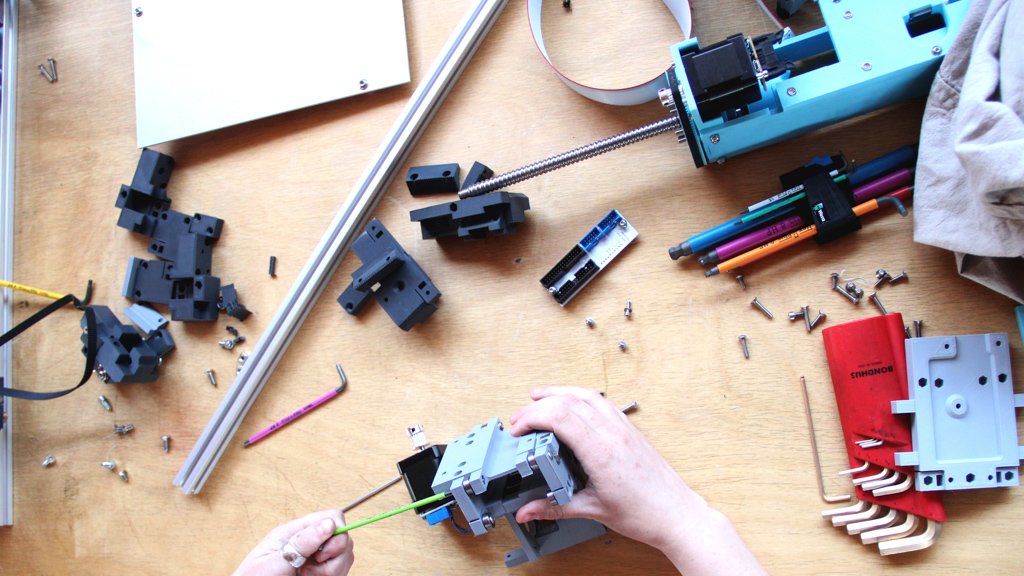

Jake Read, Samuel Schuur

Detailed origami projects can be difficult to fold; this machine pre-creases sheets of paper using a pressure-loaded roller tool which is mounted on a rotating "theta" axis, making them easier to fold into their final form. It is based on a modular tool-changing machine system that can also load cutting tools, marking tools, spindles and extruders. For this project, we made substantial updates to the motion control system in the machine so as to incorporate the rotational degree of freedom that the creasing and knife-cutting tools require.

RoboLeaf

Jennifer Karson, Alan Grover, Annet Couwenberg, Jack Forman

RoboLeaf imagines a tree that can protect itself from invasive insects like the spongy moth caterpillar and artificial intelligence that allows humans to share information with trees. The prototype is of a tree branch and includes a leaf with a unique folding pattern. The folds allow the leaf to contract and protect itself from predators. The folds of this prototype were scored on a laser cutter. A newly developed fiber thread that silently contracts when heated or sent an electric current allows the leaf to contract and expand.

SuperWood

Patricia Stathatou, Miana Smith, Anjali Srinivasan, Ryan Hoover

This project experimented with transforming basswood into a much denser, stronger version of itself. The wood was cooked in a heated bath of chemicals to break down the cellular structure, and then pressure was used to compress the wood into a super-strong version.

WireStack

Marco Perry, Mason Goodson, Leo McElroy, Daniel Callahan

This project experimented with a prototype of the Pensa Labs wire bending CNC machine. Participants worked together to develop custom generative design tools to take 3D meshes and convert them into wire bending toolpaths. Small voxels and a sculpture of a bust were some of the objects created from this project.

Wire Logo is a custom programming language inspired by Logo to design wire bending patterns using a "pen" that you can navigate in 3D space.

RotaryCNC

Sallye Coyle

For this project, Sallye Coyle set up and installed a 48” rotary indexer tool on Haystack’s ShopBot PRSalpha96 machine. Once installed, she experimented with making cylindrical lithophane engravings using photographs of the landscape here on Deer Isle.

Special thanks to Jack Forman for producing the above project videos, and to Grace Gershenfeld for photography.

Presentation Recordings

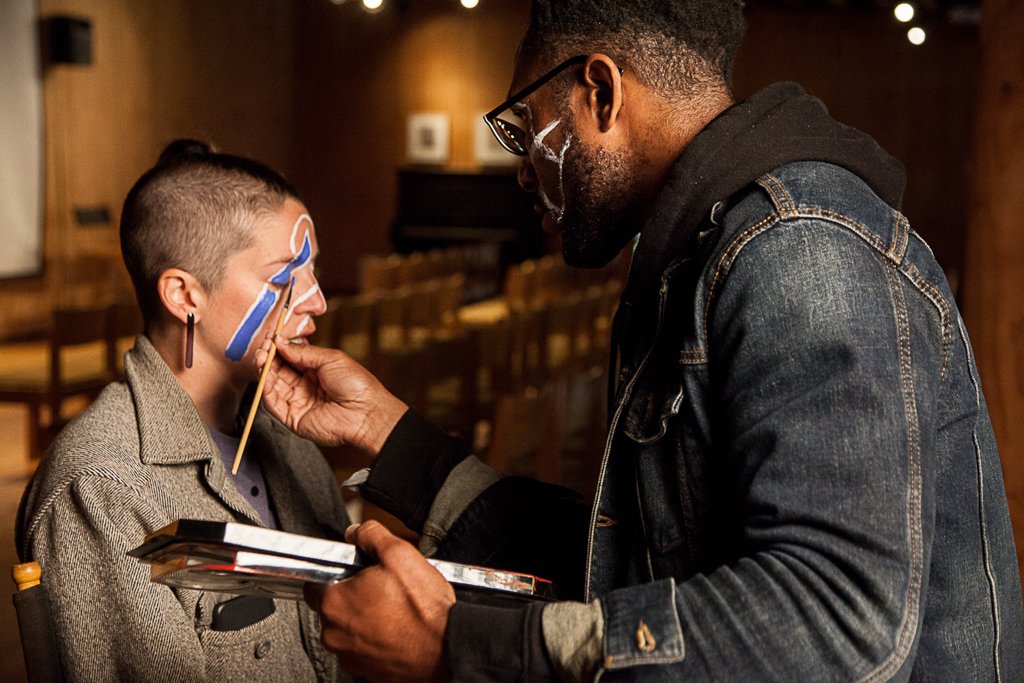

This year we ran four evening programs, each in a rapid-fire artist talk format. Participants had 5-minutes to present their work. The evenings were loosely grouped into the following categories:

Art & Impact

Machines and Architectures

Materials and Processes

Design and Interfaces

New Equipment

In the original pilot John Martincic from Forest Scientific generously donated a MakerFab Plasma Cutter to expand Haystack’s capabilities in the metal studios. This year, we had an outpouring of generosity and received the following new tools as donations to the school.

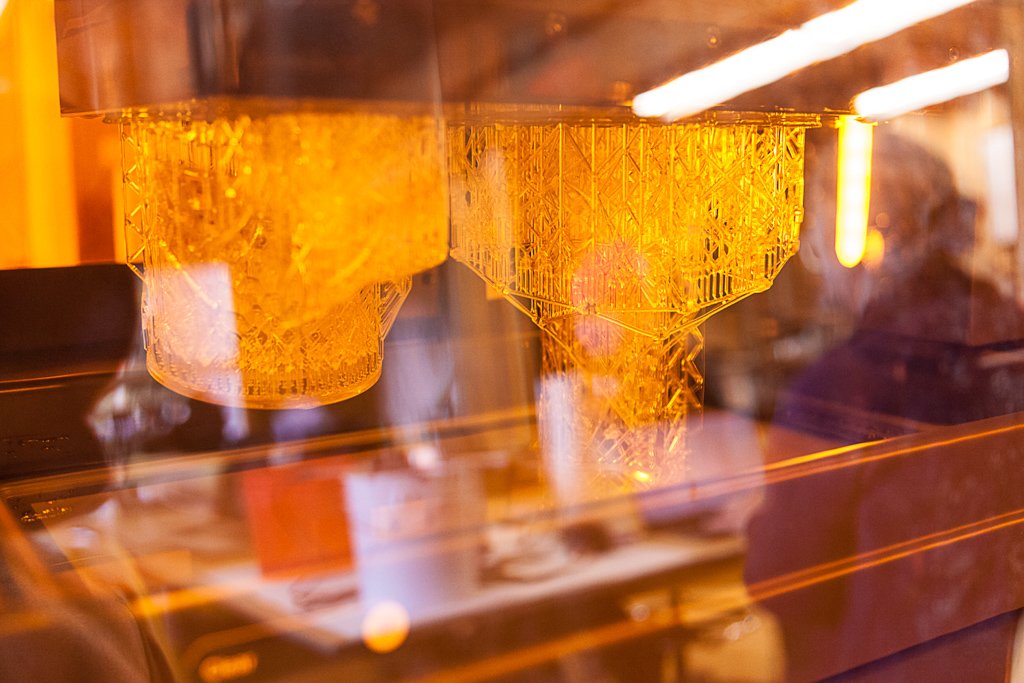

Form3L — large scale SLA 3D printer

ShopBot Rotary Indexer — large scale rotary tool for CNC milling

Bantam CNC — industrial and professional CNC milling machine

Shaper Workstation — expansion pack for the Origin milling machine

Along with these new tools, all participants invested their time in creating documentation for future artists to reap the benefits of these new processes into their work.

Form 3L SLA 3D Printer, donated by Formlabs